45kVA Three Phase Pad Mounted Transformer

The 45 kVA pad-mounted transformer meets ANSI, CSA, NEMA, IEEE, and DOE standards. NPC Electric's 45 kVA pad-mounted transformers comply with DOE efficiency values and are UL listed. Based on specific technical requirements, the iron core can be designed as either a three-legged or five-legged assembly structure.

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or Others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application EV Charging

- Power Rating 45kVA

- Certificate UL ,CESI ,DNV or SGS

- Cooling Method ONAN,KNAN

- Oil 11950V Delta

- Minerial Oil or FR3

Technical Specifications

Optional Configurations

Package and Ship

Test

Routine Test

Application

Technical Specifications

45kVA Three Phase Pad Mounted Transformer

45 kVA 11.95kV Transformer Technical Specifications

45 kVA 11.95kV Transformer Accessories

| Rated Power | 45 kVA |

| Rating Primary Voltage | 11950DELTA |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As NEMA Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 |

| Insulating Oil Weight | 370 kg |

| Total Weight | 1000 kg |

| Outline Dimensions(L×W×H)in. | 50×39×68 |

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

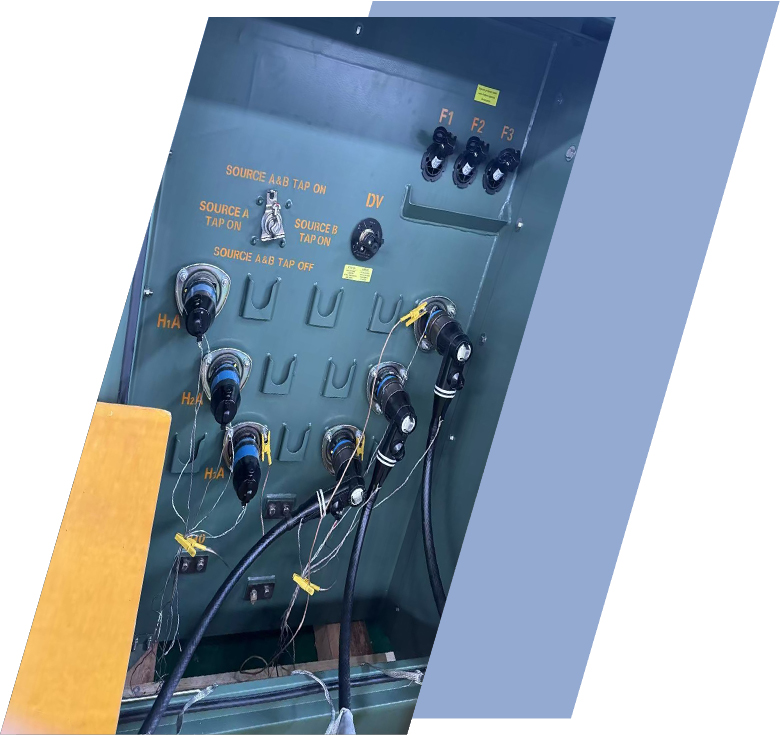

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Optional Configurations

45kVA Three Phase Pad Mounted Transformer

NPC ELECTRIC transformers offer a wide range of optional features to meet the diverse needs of electrical systems. Key options include high and low voltage bushings, such as 200 A (15kV) bushing well, feed-through inserts, and high-voltage deadbreak bushings. These ensure safe and efficient power distribution across various voltage levels.

For tank and cabinet features, we offer durable stainless steel constructions, including full stainless steel units and customizable service entrances. Additionally, features like copper ground bus bars, Kirk-Key provisions, and a nitrogen blanket enhance reliability and safety.

We also provide special designs for critical applications, seismic environments, and high altitude conditions, ensuring transformers are tailored for specific operational needs. NPC ELECTRIC transformers come with flexible switching options, such as loadbreak switches, visible break systems, and tap changers for efficient load management.

Protection features include advanced overcurrent protection like Bay-O-Net fuses, MagneX™ interrupters, and vacuum fault interrupters. Overvoltage protection with surge arresters and elbow arresters is also available to safeguard against voltage spikes.

Other options include metering packages, fan systems, and control boxes in various configurations for enhanced monitoring and control. We also offer coatings in ANSI® standard colors and custom decals for safety compliance.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

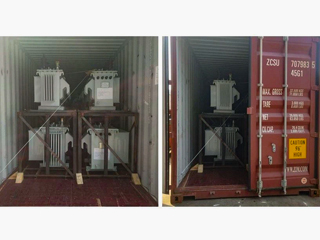

Package and Ship

45kva 11.95kv Three Phase Pad Mounted Transformer

NPC ELECTRIC three-phase transformers are designed to be securely packaged for sea freight transport, ensuring safe delivery across long distances. For this purpose, we offer wooden crate packaging that meets international shipping standards, protecting the transformer from potential damage during transit.

The sea freight wooden crates are made from high-quality, durable wood, treated to prevent moisture damage, corrosion, and pests. The crate is also reinforced to withstand the rigors of sea transport, offering superior protection from shocks and vibrations.

To enhance safety and security, the transformer is securely mounted inside the crate with anti-shift supports. This prevents any movement during transit, reducing the risk of mechanical damage. Additionally, the crate is equipped with strong, secure fastening systems to keep the transformer in place.

We ensure that all wooden crates are fully compliant with international shipping regulations, including ISPM 15 standards, to prevent any issues with customs and quarantine procedures. This makes our packaging solution both reliable and cost-effective for global shipments.

In addition to robust packaging, we provide comprehensive shipping insurance for every transformer. This insurance covers potential risks during transit, such as damage, theft, or natural disasters. By offering this coverage, we ensure peace of mind for our clients, knowing their valuable equipment is protected throughout its journey.

Whether shipping to overseas projects or international clients, our wooden crate packaging, coupled with shipping insurance, guarantees that your transformer arrives in perfect condition, ready for installation. With careful design and attention to detail, we prioritize the safety, security, and integrity of your equipment throughout the shipping process.

The sea freight wooden crates are made from high-quality, durable wood, treated to prevent moisture damage, corrosion, and pests. The crate is also reinforced to withstand the rigors of sea transport, offering superior protection from shocks and vibrations.

To enhance safety and security, the transformer is securely mounted inside the crate with anti-shift supports. This prevents any movement during transit, reducing the risk of mechanical damage. Additionally, the crate is equipped with strong, secure fastening systems to keep the transformer in place.

We ensure that all wooden crates are fully compliant with international shipping regulations, including ISPM 15 standards, to prevent any issues with customs and quarantine procedures. This makes our packaging solution both reliable and cost-effective for global shipments.

In addition to robust packaging, we provide comprehensive shipping insurance for every transformer. This insurance covers potential risks during transit, such as damage, theft, or natural disasters. By offering this coverage, we ensure peace of mind for our clients, knowing their valuable equipment is protected throughout its journey.

Whether shipping to overseas projects or international clients, our wooden crate packaging, coupled with shipping insurance, guarantees that your transformer arrives in perfect condition, ready for installation. With careful design and attention to detail, we prioritize the safety, security, and integrity of your equipment throughout the shipping process.

32

32 years of industry experience

Test

45kva 11.95kv Three Phase Pad Mounted Transformer

Raw Material Test

Before production begins, all raw materials used in the manufacturing of transformers undergo thorough testing. This ensures that every material, from copper wires to steel sheets, meets the highest industry standards. Our quality control team inspects material specifications, conducts tensile strength and conductivity tests, and checks for any potential contaminants or impurities. By carefully selecting and testing each component, we guarantee that only the best materials are used in the final product, ensuring durability, reliability, and high performance.

Active Part Test

Once the raw materials are processed into transformer components, the core body of the transformer is subjected to rigorous testing. This includes structural assessments to ensure correct assembly and proper alignment of internal parts. The core body is also tested for mechanical strength, resistance to heat, and electrical insulation properties. This phase checks for potential defects in the design or material properties, ensuring the transformer will perform efficiently even under extreme operational conditions.

FAT

After assembly, the final transformer undergoes a comprehensive series of tests to confirm its performance and safety. This includes electrical tests to verify voltage, current, and insulation resistance. We also perform temperature rise tests to ensure the transformer can operate under load without overheating. Additionally, safety tests such as overcurrent, short circuit, and dielectric tests are conducted to ensure the transformer meets all industry safety standards. Only after passing these stringent checks do we approve the finished product for delivery.

Routine Test

Insulation Power Factor

Ratio, Polarity, and Phase Relation

Winding Resistance

Impulse Tests

On load Loss Test

No Load Loss Test

Test Standard As Below:

IEEE C57.12.00 & IEEE C57.12.90 (Liquid-Immersed)

IEEE C57.12.01 & IEEE C57.12.91 (Dry-Type)

*These comprehensive tests ensure that each transformer meets performance standards and operates reliably under various conditions.

Application

Factory View

● 30+ years of manufacturing experience

● ISO and UL certified production

● Customized cable and transformer solutions

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.

Welcome your inquiry

Honesty, Integrity, Frugality, Activeness and Passion