10kVA Single Phase Pad Mounted Transformer

3.The 10 kVA pad-mounted transformer meets ANSI, CSA, NEMA, IEEE, and DOE standards. NPC Electric's 10 kVA pad-mounted transformers comply with DOE efficiency values and are UL listed. Based on specific technical requirements, the incoming line can be designed as either a loop feed or radial feed, and it also supports customized dual voltage.

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480-240/240-120or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA

- Application Residential Power Distribution,Underground Distribution Systems etc

- Power Rating 10kVA

- Certificate UL ,CESI

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Minerial Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

Optional Configurations

Packing and Shipping

Test

Routine Test

Application

Technical Specifications

5kVA Single Phase Pad Mounted Transformer

Technical Specifications

Accessories

| Technical Specifications | ||

| Rated Power | 10 kVA | |

| Rating Primary Voltage | 2.4-34.5kV | |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Ii0,Ii6 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 30 kg | |

| Total Weight | 250 kg | |

| Outline Dimensions(L×W×H)in. | 700×500×900(mm) | |

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | Non-PCB decal |

| 1" Upper Fill Valve Filter Press Connection | High Voltage Warning Signs |

Optional Configurations

10kVA Single Phase Pad Mounted Transformer

NPC ELECTRIC’s single-phase pad-mounted transformers can be fully customized to meet your specific requirements. The 10kVA Single Phase Pad Mounted Transformer offers a variety of optional specifications to meet specific operational needs. These options may include different types of insulating oils, such as mineral oil or biodegradable oil, for enhanced environmental compliance. The transformer can be equipped with on-load tap changers (OLTC) for adjusting output voltage under varying load conditions.

Additionally, temperature monitoring systems can be installed to track internal temperatures for improved performance and safety. Protection features, such as surge arresters, pressure relief devices, and fault indicators, can also be included for added reliability. For installations in harsh environments, corrosion-resistant coatings or weatherproof enclosures are available to ensure durability and longevity. These customizable specifications make the transformer suitable for a wide range of applications, offering flexibility, safety, and efficiency.

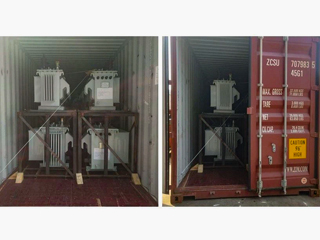

Packing and Shipping

10kVA Single Phase Pad Mounted Transformer

NPC ELECTRIC single-phase pad mounted transformers are designed to be securely packaged for sea freight transport, ensuring safe delivery across long distances. For this purpose, the Packing and Shipping process for a 10kVA Single Phase Pad Mounted Transformer is designed to ensure safe delivery to the customer, minimizing the risk of damage during transit.

The transformer is securely packed in a robust, weather-resistant wooden crate or steel container, with appropriate cushioning materials like foam or bubble wrap to absorb any shocks or impacts during transport.

The packing is carefully designed to protect the transformer from moisture, dust, and other environmental factors that could potentially affect its functionality.

For shipping, the transformer is typically delivered via road, rail, or sea, depending on the destination. It is properly secured to the shipping platform or pallet using straps or tie-downs to prevent any movement during transit.

The packaging is clearly labeled with handling instructions and safety warnings to ensure that all involved parties handle the equipment with care.

Shipping documentation, including customs clearance forms, certificates of origin, and any necessary permits, are included to comply with international shipping standards. Upon arrival, the transformer is inspected for any potential damage before installation. This thorough packing and shipping process ensures that the 10kVA Single Phase Pad Mounted Transformer reaches its destination in optimal condition, ready for installation and long-term operation.

The transformer is securely packed in a robust, weather-resistant wooden crate or steel container, with appropriate cushioning materials like foam or bubble wrap to absorb any shocks or impacts during transport.

The packing is carefully designed to protect the transformer from moisture, dust, and other environmental factors that could potentially affect its functionality.

For shipping, the transformer is typically delivered via road, rail, or sea, depending on the destination. It is properly secured to the shipping platform or pallet using straps or tie-downs to prevent any movement during transit.

The packaging is clearly labeled with handling instructions and safety warnings to ensure that all involved parties handle the equipment with care.

Shipping documentation, including customs clearance forms, certificates of origin, and any necessary permits, are included to comply with international shipping standards. Upon arrival, the transformer is inspected for any potential damage before installation. This thorough packing and shipping process ensures that the 10kVA Single Phase Pad Mounted Transformer reaches its destination in optimal condition, ready for installation and long-term operation.

32

32 years of industry experience

Test

10kVA Single Phase Pad Mounted Transformer

Progress Test

NPC Electirc manufacture pad mounted transformer have the strict quality control , The Progress Test for a 10kVA Single Phase Pad Mounted Transformer is carried out during the manufacturing process to ensure that the transformer meets all design and quality requirements. These tests include verification of the core insulation, winding resistance, and dielectric strength of the transformer. Additionally, electrical components such as bushings, tap changers, and protection devices are tested for proper functionality. The progress test also checks the transformer’s ability to handle operational loads and voltage fluctuations. Any issues identified during these tests are addressed before moving on to the final testing stages, ensuring that the transformer is reliable, safe, and ready for commissioning. These tests are essential to confirm the transformer’s performance under real-world conditions and compliance with industry standards.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor:

♦ Ratio, Polarity, and Phase Relation:

♦ Winding Resistance:

♦ Impulse Tests:

♦ On load Loss Test:

♦ No Load Loss Test

♦ Leak Test:

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

♦ Insulation Power Factor:

♦ Ratio, Polarity, and Phase Relation:

♦ Winding Resistance:

♦ Impulse Tests:

♦ On load Loss Test:

♦ No Load Loss Test

♦ Leak Test:

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

NPC Electric will tests made for quality control by the manufacturer on every device or representative samples, or on parts or materials as required, to verify during production that the product meets the design specifications.

The Transformer Factory Acceptance Test (FAT) for a 10kVA Single Phase Pad Mounted Transformer is an essential procedure conducted before shipment to ensure the transformer meets all required standards and performs optimally. During the FAT, several critical tests are carried out:

Visual Inspection: Ensuring the transformer’s physical appearance, including the enclosure, bushings, and labeling, meets design specifications.

Electrical Testing: This includes measuring winding resistance, insulation resistance, and verifying the turns ratio to confirm proper electrical functionality.

Dielectric Strength Test: Applying high voltage to the transformer to test its insulation system, ensuring it can withstand normal operating and transient voltage conditions.

Load Testing: Simulating real-world operational conditions to verify the transformer’s performance under load, checking voltage regulation and efficiency.

Protection Device Testing: Confirming that safety features such as surge arresters, tap changers, and other protective components function properly.

The FAT ensures the 10kVA Single Phase Pad Mounted Transformer is reliable, safe, and ready for installation, guaranteeing compliance with industry standards before being dispatched to the customer.

The Transformer Factory Acceptance Test (FAT) for a 10kVA Single Phase Pad Mounted Transformer is an essential procedure conducted before shipment to ensure the transformer meets all required standards and performs optimally. During the FAT, several critical tests are carried out:

Visual Inspection: Ensuring the transformer’s physical appearance, including the enclosure, bushings, and labeling, meets design specifications.

Electrical Testing: This includes measuring winding resistance, insulation resistance, and verifying the turns ratio to confirm proper electrical functionality.

Dielectric Strength Test: Applying high voltage to the transformer to test its insulation system, ensuring it can withstand normal operating and transient voltage conditions.

Load Testing: Simulating real-world operational conditions to verify the transformer’s performance under load, checking voltage regulation and efficiency.

Protection Device Testing: Confirming that safety features such as surge arresters, tap changers, and other protective components function properly.

The FAT ensures the 10kVA Single Phase Pad Mounted Transformer is reliable, safe, and ready for installation, guaranteeing compliance with industry standards before being dispatched to the customer.

Insulation Power Factor

Purpose of Testing:

The purpose of testing the insulation power factor is to evaluate the dielectric loss of the insulation system in electrical equipment, and to determine whether issues such as moisture ingress, aging, or contamination are present. A high power factor value usually indicates insulation deterioration.

Testing Equipment:

Insulation power factor tester (e.g., brands like Doble, Megger)

Voltage source (typically 1 kV, 2.5 kV, or 10 kV or as the customer request standard)

Temperature and humidity meter (for recording environmental conditions)

Voltage source (typically 1 kV, 2.5 kV, or 10 kV or as the customer request standard)

Temperature and humidity meter (for recording environmental conditions)

Pre-Test Preparation:

De-energize tap changer the equipment and ensure it has been properly grounded and discharged.

Make sure the bushings and terminal connections to prevent surface contamination from affecting test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20–30°C).

Calibrate and inspect the test instruments to ensure they are in good working condition.

Make sure the bushings and terminal connections to prevent surface contamination from affecting test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20–30°C).

Calibrate and inspect the test instruments to ensure they are in good working condition.

Test Progress:

Connect the Test Instrument:

Connect the test equipment to the bushings or terminals of the equipment under test and ensure proper grounding.

Apply Test Voltage:

Select the appropriate test voltage according to the rated voltage of the equipment (e.g., 25 kV for high-voltage windings or as the request of the pad mounted transformer).

Connect the test equipment to the bushings or terminals of the equipment under test and ensure proper grounding.

Apply Test Voltage:

Select the appropriate test voltage according to the rated voltage of the equipment (e.g., 25 kV for high-voltage windings or as the request of the pad mounted transformer).

Measure and Record:

Start the test and record the following parameters:

Capacitive current (IC)

Power current (IW)

Power factor (PF) or dissipation factor (Tanδ)

Capacitance

Ambient temperature and humidity at the time of testing

Capacitive current (IC)

Power current (IW)

Power factor (PF) or dissipation factor (Tanδ)

Capacitance

Ambient temperature and humidity at the time of testing

Temperature Correction:

Correct the measured power factor to the reference temperature (typically 20°C) for accurate evaluation.

Repeat Testing (if necessary):

Measure different windings (high-voltage, medium-voltage, low-voltage) and bushings separately for comparative analysis.

Evaluation Criteria (Reference):

Insulation power factor ≤ 0.5% (Excellent)

0.5% < Power factor ≤ 1% (Good)

1% (Further inspection or corrective action required)

Test standard:IEEE C57.12.00 & IEEE C57.12.90 (Liquid-Immersed)

0.5% < Power factor ≤ 1% (Good)

1% (Further inspection or corrective action required)

Test standard:IEEE C57.12.00 & IEEE C57.12.90 (Liquid-Immersed)

*These comprehensive tests ensure that each transformer meets performance standards and operates reliably under various conditions.

Application

Residential Power Distribution,Underground Distribution Systems etc

Factory View

● 30+ years of manufacturing experience

● ISO and UL certified production

● Customized cable and transformer solutions

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.

Welcome your inquiry

Honesty, Integrity, Frugality, Activeness and Passion