35kV Power Transformer

The 35kV Power transformer complies with ANSI, CSA, NEMA, IEEE, IEC, GB, and DOE standards. NPC ELECTRIC manufactures Dry type transformer in strict accordance with the highest industry and international standards. Our team of highly skilled professionals ensures these rigorous standards are meticulously upheld in daily operations.

- Primary Voltage Ratings 35, 34.5, 33 or others

- Secondary Voltage Ratings 480/277V,400/230V,380/220V or customized

- H.V. Tap Range ± 2×2.5% ,± 3×2.5% HV taps or others

- Type Oil-immersed power transformer

- BIL 200kV

- Standards IEEE, ANSI, NEMA,IEC,GB

- Application High-rise buildings, commercial centers, theaters, hospitals, hotels etc.

- Power Rating 5000-400000kVA

- Certificate UL ,CESI

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

Key Features

Packing and Shipping

Transformer Manufacturer Progress Test

Routine Test

Application

Technical Specifications

35kV Power Transformer

Technical Specifications

Accessories

| Technical Specifications | ||

| Rated Power | 5000-400000kVA | |

| Rating Primary Voltage | 35kV,34.5kV,33kV | |

| Secondary Voltage | 6.6kV 10kV 13.8kV Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11,YD11,YNd11 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE,CAS Std or Customized | |

| Impedance Voltage | As IEC | |

| Altitude | ≤1,000m or Customized | |

| Enclosure material | Mid Steel | |

| Insulating Oil Weight | ||

| Total Weight | ||

| Outline Dimensions(L×W×H)in. | ||

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Key Features

35kV Power Transformer

NPC ELECTRIC's 35kV oil-immersed power transformers are designed for high performance, reliability, and adaptability across various industrial and environmental applications. These transformers are safe, fire-resistant, and environmentally friendly, allowing for direct operation in load centers without additional protective measures. Constructed to withstand short-circuit conditions with minimal partial discharge, they ensure thermal stability and long-term reliability. Equipped with effective cooling mechanisms, including forced air cooling options, they enhance operational capacity and maintain optimal performance. The transformer surfaces undergo oil removal, rust elimination, and sandblasting before being coated with moisture-resistant paint, making them suitable for harsh environments like metallurgy and petrochemical industries.

Their compact size and reduced weight facilitate easier transportation and installation, especially in confined spaces. A robust positioning structure between the core and oil tank prevents displacement during transportation, ensuring stability throughout the transformer's operational life. Utilizing high-permeability, low-loss silicon steel sheets with multi-level fully oblique joints, they minimize no-load losses and operational noise. Coils made from suitable conductors like paper-insulated or self-adhesive transposed wires effectively lower load losses, contributing to overall energy efficiency. These features collectively contribute to the transformer's high efficiency, low operational losses, and suitability for various demanding applications.

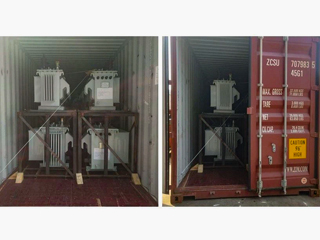

Packing and Shipping

35kV Power Transformer

NPC ELECTRIC’s 35kV oil-immersed power transformers are meticulously packaged for secure sea freight and long-distance transport, ensuring they arrive at their destination in perfect condition and ready for installation. For a 35kV oil-immersed power transformers, the packing and shipping process is carefully engineered to minimize the risk of damage during transit.

Each transformer is enclosed in a durable, weather-resistant wooden crate or steel-reinforced container, with internal cushioning materials such as high-density foam or shock-absorbing padding to protect against vibration, impact, and shifting. The packaging is designed to shield the transformer from moisture, dust, and other environmental factors that could compromise performance.

During shipping—whether by road, rail, or sea—the transformer is securely fastened to a pallet or transport platform using heavy-duty straps or tie-downs to prevent movement. Clear handling instructions, safety warnings, and directional indicators are prominently displayed on the packaging to ensure proper handling by logistics personnel.

All necessary shipping documentation is provided, including customs clearance paperwork, certificates of origin, and any required permits, ensuring full compliance with international transport regulations. Upon delivery, a thorough visual inspection is conducted to verify the transformer's integrity before installation.

Each transformer is enclosed in a durable, weather-resistant wooden crate or steel-reinforced container, with internal cushioning materials such as high-density foam or shock-absorbing padding to protect against vibration, impact, and shifting. The packaging is designed to shield the transformer from moisture, dust, and other environmental factors that could compromise performance.

During shipping—whether by road, rail, or sea—the transformer is securely fastened to a pallet or transport platform using heavy-duty straps or tie-downs to prevent movement. Clear handling instructions, safety warnings, and directional indicators are prominently displayed on the packaging to ensure proper handling by logistics personnel.

All necessary shipping documentation is provided, including customs clearance paperwork, certificates of origin, and any required permits, ensuring full compliance with international transport regulations. Upon delivery, a thorough visual inspection is conducted to verify the transformer's integrity before installation.

32

32 years of industry experience

Transformer Manufacturer Progress Test

35kV Power Transformer

Progress Test

NPC Electric manufactures high-quality three-phase 35kV oil-immersed power transformers under strict quality control protocols. During production, a comprehensive Progress Test is conducted on each unit to ensure full compliance with design specifications and quality standards. This process includes verification of core insulation, winding resistance, and dielectric strength. Key electrical components such as bushings, tap changers, and protection devices are also tested to confirm proper functionality. The transformer’s ability to withstand operational loads and voltage fluctuations is thoroughly assessed. Any deviations or issues identified are promptly addressed before proceeding to final testing. These rigorous progress tests ensure that every dry-type transformer delivered is safe, reliable, and fully prepared for real-world operation, while meeting all relevant industry standards.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor:

♦ Ratio, Polarity, and Phase Relation:

♦ Winding Resistance:

♦ Impulse Tests:

♦ On load Loss Test:

♦ No Load Loss Test

♦ Leak Test:

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

♦ Insulation Power Factor:

♦ Ratio, Polarity, and Phase Relation:

♦ Winding Resistance:

♦ Impulse Tests:

♦ On load Loss Test:

♦ No Load Loss Test

♦ Leak Test:

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

NPC Electric conducts rigorous quality control testing on every transformer or representative samples, as well as on specific components and materials, to ensure compliance with design specifications throughout the production process.

The Factory Acceptance Test (FAT) for a 30kVA three-phase dry-type transformer is a critical step performed before shipment to verify that the unit meets all applicable standards and delivers optimal performance. The FAT includes the following key procedures:

Visual Inspection: Evaluates the transformer’s physical condition, including the enclosure, terminals, and labeling, to ensure conformance with design and safety requirements.

Electrical Testing: Involves measuring winding resistance, insulation resistance, and performing turns ratio tests to validate electrical integrity and functionality.

Dielectric Strength Test: Applies high voltage across the insulation system to ensure it can endure both normal and transient operating voltages without failure.

Load Testing: Simulates real-world operating conditions to assess the transformer’s voltage regulation, temperature rise, and overall efficiency under load.

Protection Device Testing: Verifies the proper operation of integrated protective components such as thermal sensors, temperature relays, and tap changers (if applicable).

These comprehensive tests ensure that each 30kVA power transformer is safe, reliable, and fully compliant with industry standards, providing peace of mind before delivery and installation.

The Factory Acceptance Test (FAT) for a 30kVA three-phase dry-type transformer is a critical step performed before shipment to verify that the unit meets all applicable standards and delivers optimal performance. The FAT includes the following key procedures:

Visual Inspection: Evaluates the transformer’s physical condition, including the enclosure, terminals, and labeling, to ensure conformance with design and safety requirements.

Electrical Testing: Involves measuring winding resistance, insulation resistance, and performing turns ratio tests to validate electrical integrity and functionality.

Dielectric Strength Test: Applies high voltage across the insulation system to ensure it can endure both normal and transient operating voltages without failure.

Load Testing: Simulates real-world operating conditions to assess the transformer’s voltage regulation, temperature rise, and overall efficiency under load.

Protection Device Testing: Verifies the proper operation of integrated protective components such as thermal sensors, temperature relays, and tap changers (if applicable).

These comprehensive tests ensure that each 30kVA power transformer is safe, reliable, and fully compliant with industry standards, providing peace of mind before delivery and installation.

Routine Test

Insulation Power Factor

Ratio, Polarity, and Phase Relation

Winding Resistance

Impulse Tests

On Load Loss Test

No Load Loss Test

Test Standard As Below:

IEEE C57.12.00 & IEEE C57.12.90 (Liquid-Immersed)

IEEE C57.12.01 & IEEE C57.12.91 (Dry-Type)

IEEE C57.12.01 & IEEE C57.12.91 (Dry-Type)

*These comprehensive tests ensure that each transformer meets performance standards and operates reliably under various conditions.

Application

High-rise buildings, commercial centers, theaters, hospitals, hotels etc.

Factory View

● 30+ years of manufacturing experience

● ISO and UL certified production

● Customized cable and transformer solutions

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.

Welcome your inquiry

Honesty, Integrity, Frugality, Activeness and Passion